TPE performance (Health & Beauty - Beauty)

Item ID 9474398 in Category: Health & Beauty - Beauty

TPE performance | |

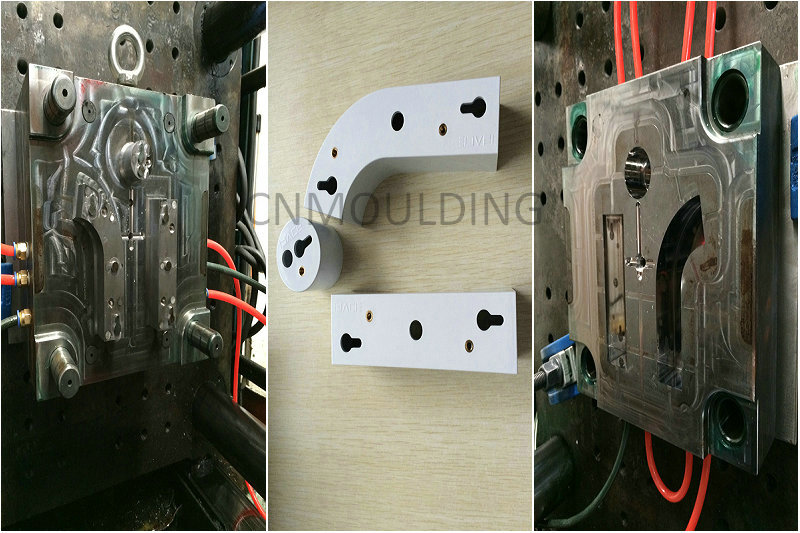

TPE thermoplastic elastomer used in ordinary transparent toys, sports equipment, and so on. The TPE is rubber with high elasticity, high strength, high resilience. But also has the characteristics of injection molding materials. Environmental protection, non-toxic safety. A wide range of applications, excellent coloring, soft-touch, weather ability, fatigue and temperature resistance, superior processing performance. No vulcanization can reduce the cost of recycling, both injection molding, And PP, PE, PC, PS, ABS. And another substrate coating adhesion can also be a separate molding. The TPE (Thermoplastic Elastomer) is a widely used material in various industries due to its unique properties. It is a versatile material that combines the properties of rubber and plastic, making it an ideal choice for various applications. In this blog post, we will discuss the performance of TPE and how it can benefit different industries. One of the most significant advantages of TPE is its excellent elasticity. Can be stretched up to 700% of its original length and still return to its original shape. This property makes it an ideal choice for applications that require flexibility and durability, such as footwear, automotive parts, and medical devices. TPE is also resistant to chemicals, oils, and UV radiation. This makes it suitable for outdoor applications such as roofing materials, garden hoses, and automotive parts. It can withstand extreme temperatures ranging from -60°C to 135°C, making it an ideal choice for applications that require resistance to high or low temperatures. Another advantage of TPE is its ease of processing. Can be easily molded into complex shapes using injection molding, extrusion, or blow molding techniques. This makes it an ideal choice for applications that require intricate designs and shapes. TPE is also a sustainable material that can be recycled and reused. It does not produce harmful emissions during production and does not release toxic substances during disposal. This makes it an eco-friendly choice for various applications. In the medical industry TPE is widely used for manufacturing medical devices such as catheters, syringe tips, and surgical instruments. Its biocompatibility and non-toxicity make it an ideal choice for medical applications. In the automotive industry The TPE is used for manufacturing various parts such as seals, gaskets, and hoses. Its resistance to chemicals and extreme temperatures makes it an ideal choice for automotive applications. In the consumer goods industry TPE is used for manufacturing various products such as toys, sports equipment, and household items. Its flexibility, durability, and ease of processing make it an ideal choice for consumer goods applications. In conclusion, TPE is a versatile material that offers excellent performance and benefits various industries. Its unique properties make it an ideal choice for applications that require flexibility, durability, resistance to chemicals and extreme temperatures, and ease of processing. Its sustainability and eco-friendliness make it an ideal choice for a greener future.  | |

| Related Link: Click here to visit item owner's website (1 hit) | |

| Target Nation: All Nations Target City : shanghai Last Update : 20 February 2024 3:48 AM Number of Views: 101 | Item Owner : chinamoldmaker Contact Email: Contact Phone: 021-52913487 |

| Friendly reminder: Click here to read some tips. | |

© 2025 UKAdsList.com

USNetAds.com | GetJob.us | CANetAds.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-01-23 (0.223 sec)