S5-PVDF-175 175℃ PVDF Thin Wall Heat Shrink Tube (Business Opportunities - Marketing & Sales)

UKAdsList > Business Opportunities > Marketing & Sales

Item ID 9577920 in Category: Business Opportunities - Marketing & Sales

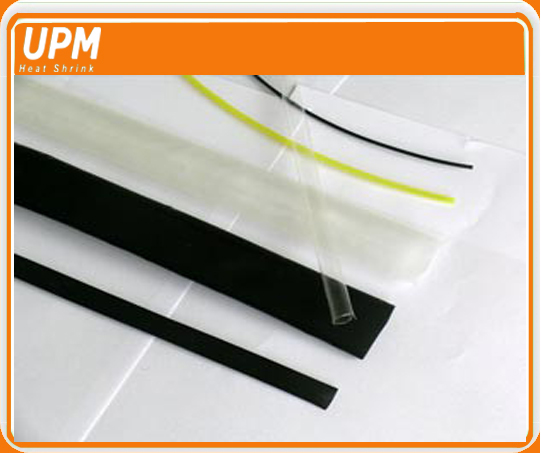

S5-PVDF-175 175℃ PVDF Thin Wall Heat Shrink Tube | |

S5-PVDF-175 175℃ PVDF Thin Wall Heat Shrink Tube Introduction A flame-retardant, semirigid, very thin wall insulation tube. Suitable for applications requiring high-temperature performance, outstanding abrasion and cut-through resistance, superior chemical and solvent resistance properties. Transparent tubing for easy see-through inspection. Features Operating temperature: -55 to 175°C Minimum full recovery temperature: 175°C Shrink ratio: 2:1 Environmental friendly, RoHS compliant Standard Color: Clear Excellent flame retardant Technical Data Property Test Method Requirement Specific gravity ASTM D2671 1.80 g/cm3 max.. Longitudinal Change ASTM D2671 -10% to +5% Tensile strength ASTM D2671 34.5 MPa min. Ultimate elongation ASTM D2671 150% min. Secant modulus (expanded) ASTM D2671 690 MPa min. Clarity Stability (175°C/24hrs) ASTM D2671 The markings in the sample are clearly visible Low-temperature flexibility (-55°C/4hrs) AMS-DTL-23053/8 No cracking Heat shock (300°C/4hrs) AMS-DTL-23053 No dripping, flowing or cracking "Heat resistance (250°C/168hrs) Ultimate elongation" ASTM D2671 " 50% min." "Vacuum Outgassing TML (Total Mass Loss) VCM (Volatile Condensable Material)" ASTM E 595 " 1.0% max. 0.1% max." "Dielectric strength Sizes 1.2/0.6 through 12.7/6.4 Sizes 19.1/9.5 through 76.2/38.1" ASTM D2671 " 31.5 kV/mm min. 23.6 kV/mm min." Volume resistivity ASTM D2671 1×1013 Ω·cm min. Water absorption (23°C/24hrs) ASTM D2671 0.5% max. Copper mirror corrosion (175°C/16hrs) "ASTM D2671 Procedure A" Non-Corrosive "Copper Contact (175°C/168hrs) Followed by test for:" "ASTM D 2671 Procedure B" No pitting or blackening of copper Ultimate elongation ASTM D2671 100% min Flammability (Average Time of Burning) UL224 15 seconds max. "Fungus Resistance Followed by tests for:" ISO 846 Method B " " " Tensile Strength Ultimate Elongation" ASTM D2671 "34.5 Mpa min. 150% min." " Dielectric Strength Sizes 1.2/0.6 through 12.7/6.4 Sizes 19.1/9.5 through 76.2/38.1" ASTM D2671 " 31.5 kV/mm min. 23.6 kV/mm min." "Fluid Resistance 24 hours at 23 ± 3°C (73 ± 5°F) JP-8 Fuel (MIL-T-83133) Skydrol* 500 Hydraulic Fluid (MIL-H-5606) Aviation Gasoline 100/130 (ASTM D910) Salt Water (5% salt) Anti-icing Fluid (AMS1424) Lubricating Oil (MIL-L-7808) Followed by tests for:" ASTM D2671 Tensile strength ASTM D2671 34.5 Mpa min. " Dielectric Strength Sizes 1.2/0.6 through 12.7/6.4 Sizes 19.1/9.5 through 76.2/38.1" ASTM D2671 " 27.6 kV/mm min. 19.7 kV/mm min." Dimension Size As supplied(mm) After recovered (mm) "Inner diameter D (min.)" "Inner diameter d (max.)" "Wall thickness t (nom.)" S5-PVDF-175-1.2/0.6 1.2 0.6 0.25 S5-PVDF-175-1.6/0.8 1.6 0.8 0.25 S5-PVDF-175-2.4/1.2 2.4 1.20 0.25 S5-PVDF-175-3.2/1.6 3.2 1.60 0.25 S5-PVDF-175-4.8/2.4 4.8 2.4 0.25 S5-PVDF-175-6.4/3.2 6.4 3.2 0.30 S5-PVDF-175-9.5/4.8 9.5 4.8 0.30 S5-PVDF-175-12.7/6.4 12.7 6.4 0.30 S5-PVDF-175-19.1/9.5 19.1 9.5 0.43 S5-PVDF-175-25.4/12.7 25.4 12.7 0.48 S5-PVDF-175-38.1/19.1 38.1 19.1 0.51 S5-PVDF-175-50.8/25.4 50.8 25.4 0.58 Cross Reference Tyco-Raychem: RW-175 / Kynar  | |

| Target Nation: All Nations Target City : All Cities Last Update : 29 August 2024 4:04 AM Number of Views: 118 | Item Owner : Lily Contact Email: Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

UKAdsList > Business Opportunities > Marketing & Sales

© 2025 UKAdsList.com

USNetAds.com | GetJob.us | CANetAds.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-04-22 (0.223 sec)