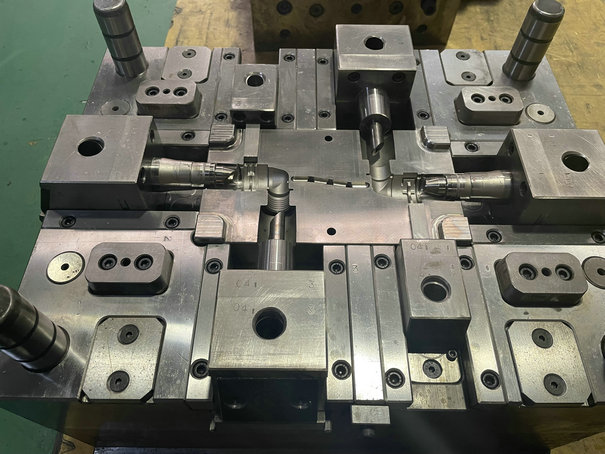

runner molding system (Automobiles & Vehicles - Auto Parts & Services)

UKAdsList > Automobiles & Vehicles > Auto Parts & Services

Item ID 9580141 in Category: Automobiles & Vehicles - Auto Parts & Services

runner molding system | |

A hot runner system is a technology used in injection molding machines to keep the plastic material in a molten state while it is being injected into the mold cavity. The system consists of a heated manifold, which is connected to a series of nozzles that deliver the molten plastic into the mold. Advantages of Hot Runner System Better gate quality: As the plastic material remains in its molten state, the gate quality is better, and there are fewer chances of defects in the final product. Material savings: As the plastic material remains in its molten state, there is less wastage of material, and hence, the material savings are significant. Faster cycle times: The hot runner system allows for faster cycle times, which means more parts can be produced in a given amount of time. Reduced labor costs: As the system is automated, it reduces the need for manual labor, resulting in reduced labor costs. Flexibility: The hot runner system is flexible and can be used with a variety of materials, including high-temperature plastics.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target Nation: All Nations Target City : shanghai Last Update : 02 September 2024 9:47 AM Number of Views: 78 | Item Owner : injectionmoldchina Contact Email: Contact Phone: 021-52913487 |

| Friendly reminder: Click here to read some tips. | |

UKAdsList > Automobiles & Vehicles > Auto Parts & Services

© 2025 UKAdsList.com

USNetAds.com | GetJob.us | CANetAds.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com | USAOnlineClassifieds.com

2025-04-04 (0.229 sec)